High productive manufacturing of Gears with CNC turning centers.

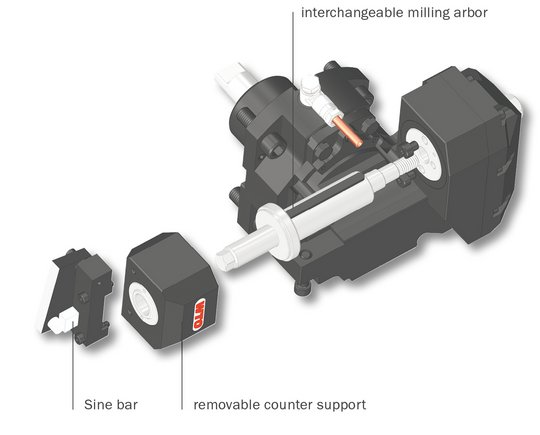

The Gear Hobbing unit offers high stiffness and runout accuracy. High flexibility due to interchangeable milling arbors for different cutting tools.

Interchangeable milling arbor – removable counter support

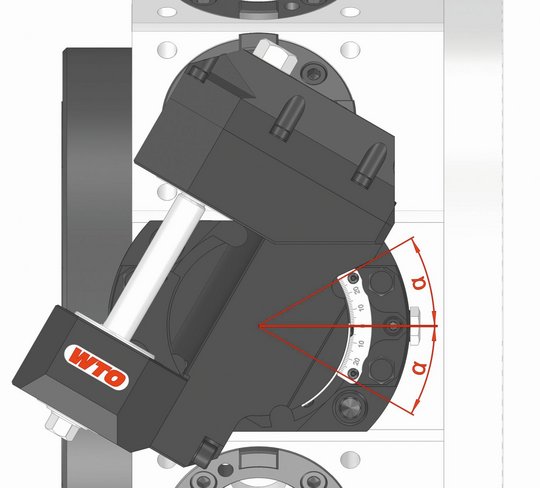

Angular adjustment ±30° with scale and vernier

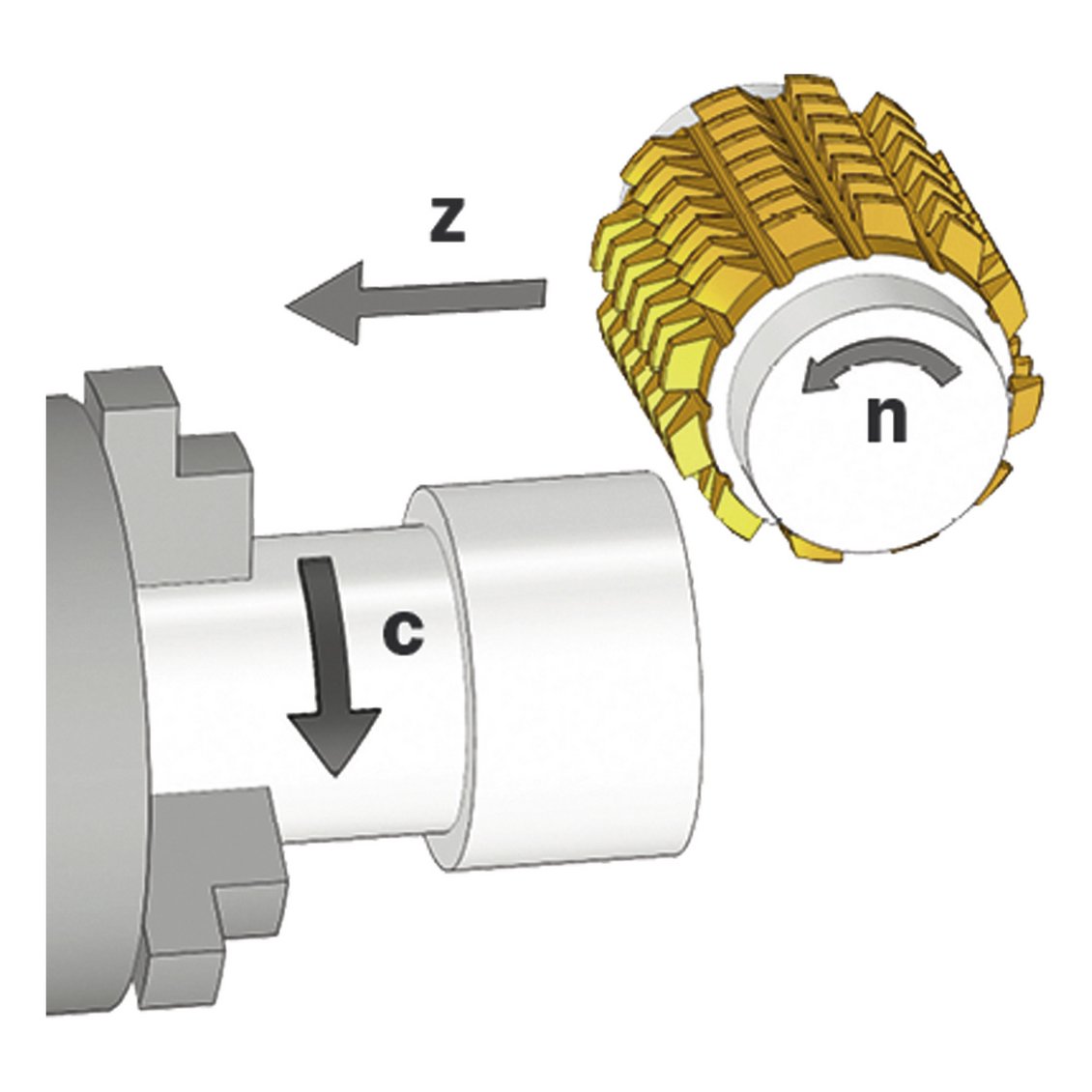

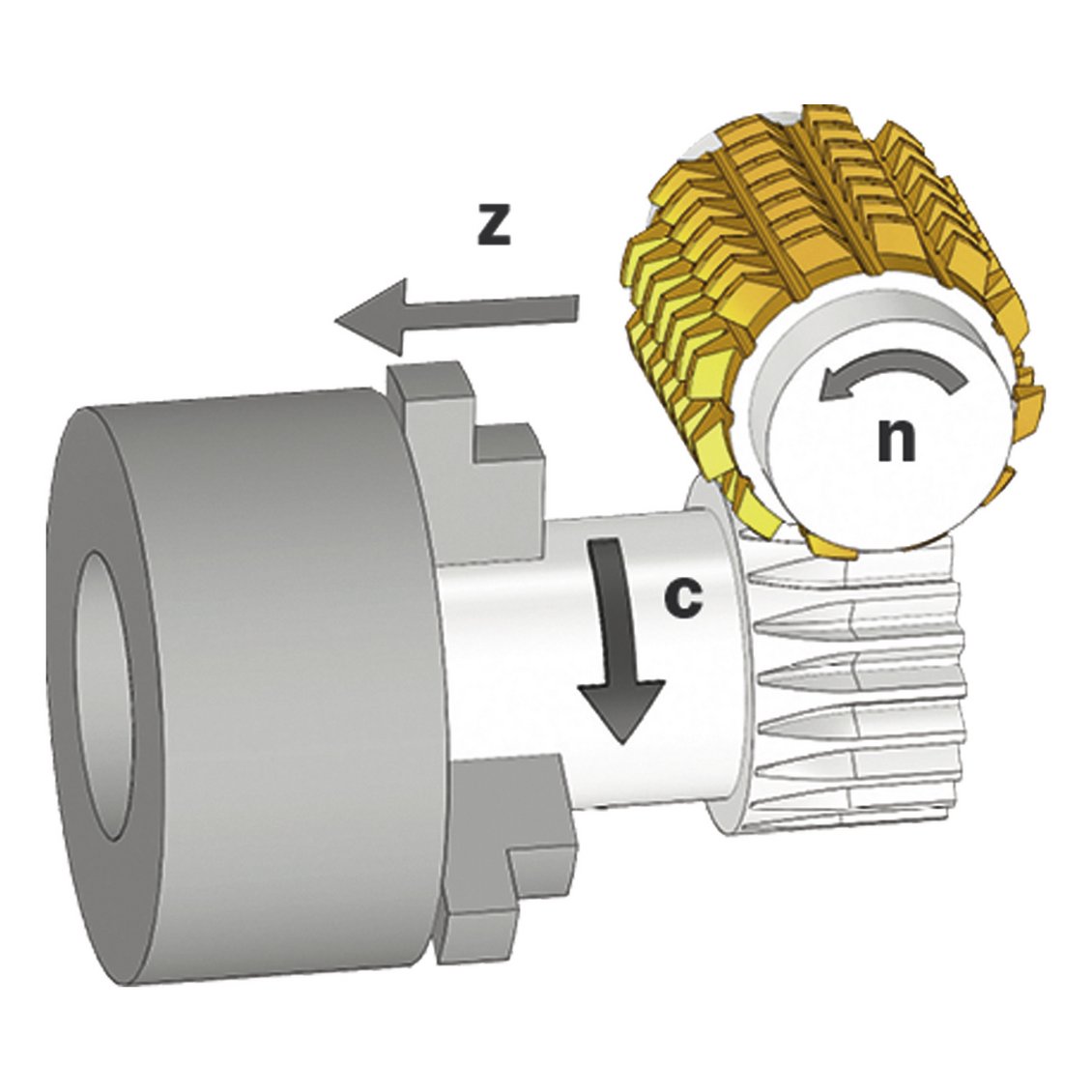

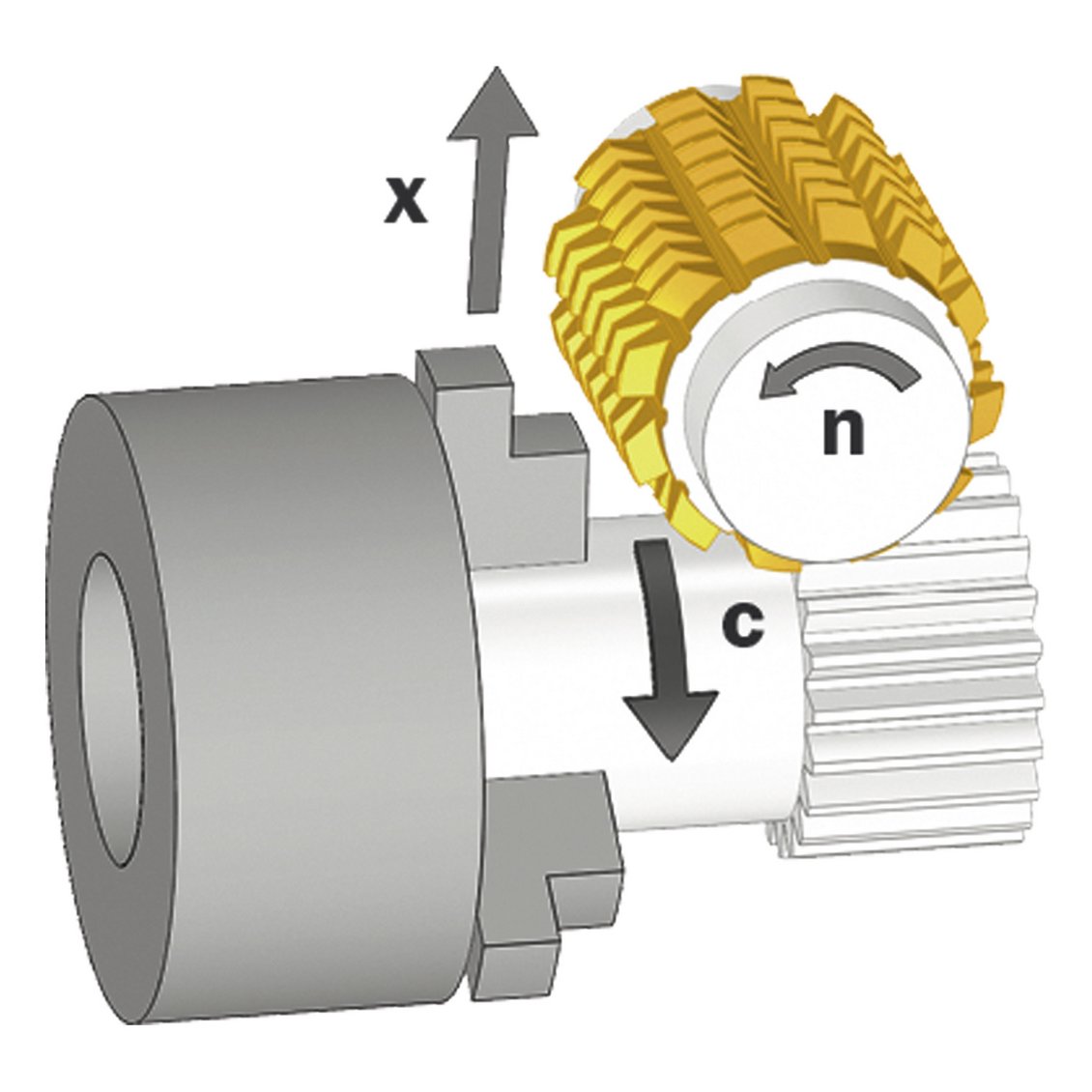

Synchronization of work piece and tool rotation.

Feed movement in Z axis.

When hobbing is finished the hob has to move towards X.

Please consider:

At the end of the gear/spline there has to be sufficient clearance for the hob.

Splines

e.g. DIN 5480, DIN 5482, TORX

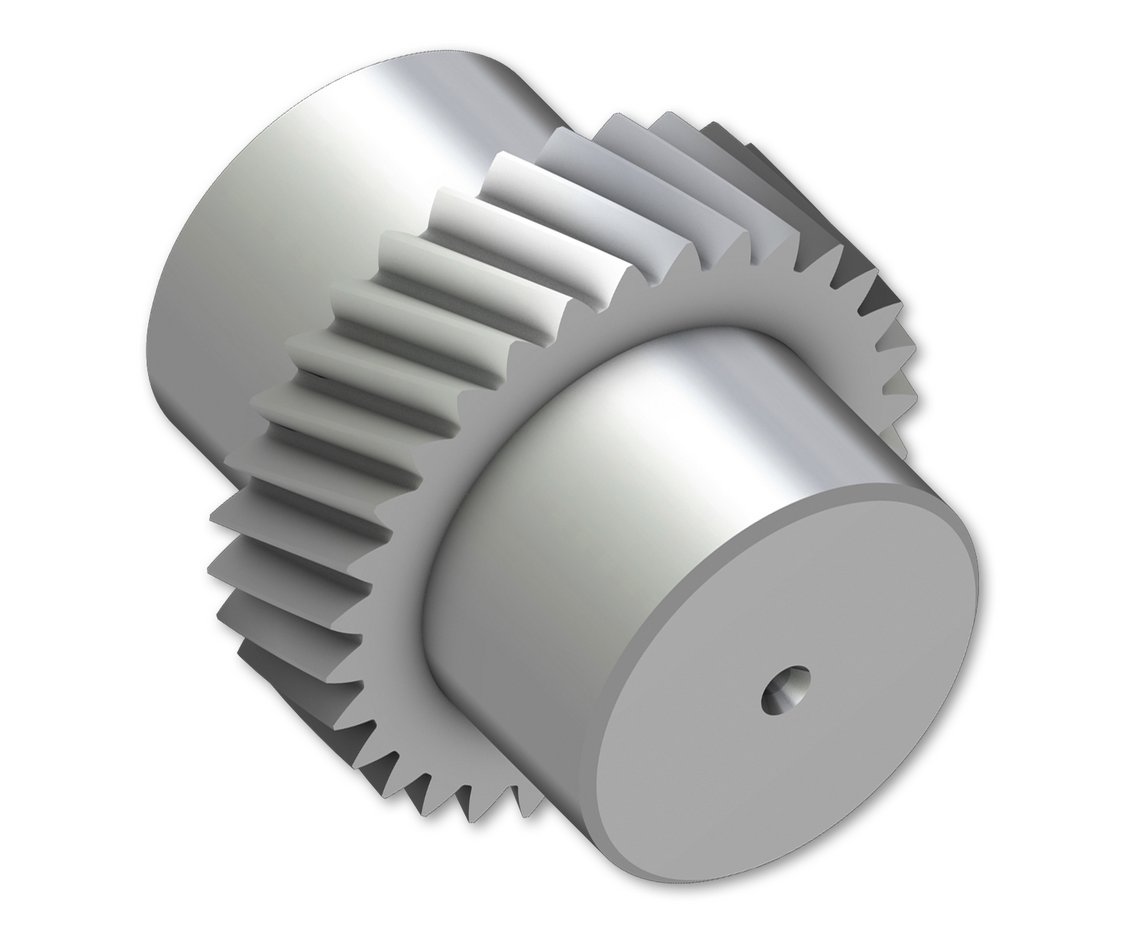

Spur gear

Helical gear

Gear Hobbing Unit (PDF, 1,3 MB)

Product Portfolio (PDF, 4,2 MB)

Please refer to our Online Catalog for the precision toolholders that are suitable for your machine: