We are very pleased about this recognition as official partner in the DNVP Partner Program and look foward to an excellent collaboration in the future.

During the official announcement in november 2025, Wilhelm Hohnen, Business Development Manager at DN Solutions presented the DNVP Partner Label to our Sales Director Daniel Sierra.

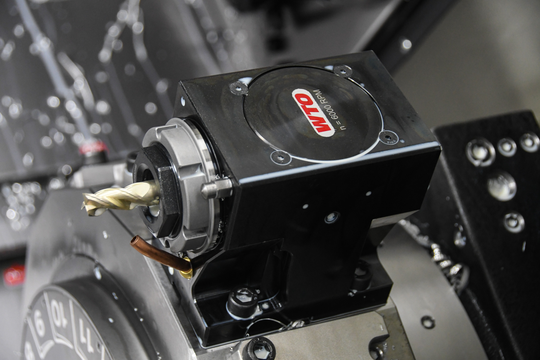

Our partnership helps customers unlock the full potential of their DN Solutions turning centres.

With our innovative toolholder solutions — precisely tailored to customer needs and machine requirements — highly accurate parts can be manufactured with maximum productivity and efficiency.

We look forward to many more successful projects together!

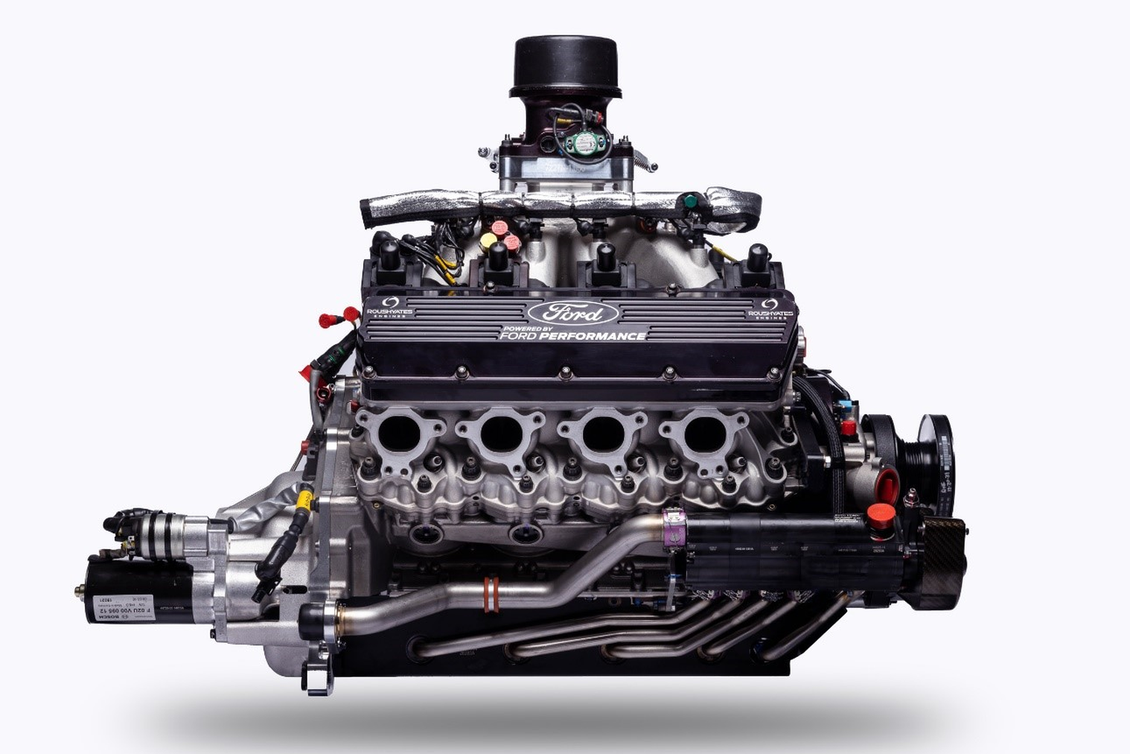

Congratulations to the Ford Motor Company and our partner Roush Yates Engines for winning the NASCAR CUP & XFINITY Championship 2023.

WTO USA is a proud partner of Roush Yates and supports Roush Yates Manufacturing Solutions with smart driven Tool Holders to manufacture efficiently engine and other race components.

WTO, a German-based company, designs and manufactures technological top-quality precision Tool Holders and tooling systems for turning centers, Multi-axis mill turns, and Swiss type lathes. In addition, WTO’s CoolSpeed ultra-high-speed spindles can run up to 80,000 rpm and are designed to optimize high speed machining. WTO USA out of Charlotte, North Carolina has been providing professional after-sales service and qualitative superior products for Roush Yates Engines (RYE) and Roush Yates Manufacturing Solutions (RYMS) to increase productivity and tool life.

“WTO is a technology-driven organization and their employees continue to provide invaluable solutions to our team,” said Todd English, VP Strategic Partnerships & Marketing at Roush Yates Engines. “As a global market leader, WTO develops state of the art technology to maximize productivity for manufacturing facilities across the globe. It is critical that we align our organization with world class companies to support our internal engine component machining as well as machining for other forms of motorsports, aerospace, defense, space, and medical markets at RYMS, where failure is not an option.”

WTO’s new generation of Smart Driven Tool Holders with intelligent online process monitoring for high process reliability will allow RYE and RYMS to monitor online critical data:

Condition monitoring of the assigned machines

CoolSpeed® mini is a new, high-speed, turbine-driven spindle. You can efficiently turn any machine into an ultra-high-speed machining center. WTO’s CoolSpeed® Ultra High-Speed Spindles for micro machining applications provides:

Dynamic run-out of 4 microns or better

“We have used WTO’s innovative products for many years and look forward to leveraging the new Smart Driven Tool Holders” Dan Keenan, VP of Engineering and Quality at Roush Yates Manufacturing Solutions. “This new smart technology will provide significant data to optimize the life of the tool holder and minimize machine downtime.”

“WTO is proud to partner with Roush Yates, a world-class race engine company competing at the highest levels of the Motorsports Industry,” said Vice President, Patrick Diener. “We are committed to providing our latest manufacturing solutions to Roush Yates to supporting them in their continuous improvement process.”

About Roush Yates Engines:

Roush Yates Engines is a leading-edge engine development company based in Mooresville, NC consisting of two state-of-the-art facilities - Roush Yates Engines and Roush Yates Manufacturing Solutions. The company’s core business includes designing, building, and testing purpose-built race engines.

Roush Yates Engines (RYE) in partnership with Ford Performance is the exclusive engine builder of the NASCAR FR9 Ford V8 engine and Ford Mustang 5.2L V8 engine, used in the IMSA Michelin Pilot Challenge series.

Roush Yates Manufacturing Solutions is an AS9100 Rev D/ ISO 13485 high precision machining division of RYE. Our expertise is in the CNC machining of complex geometry parts for critical applications that require robust process control and post machine surface treatments. We provide an array of automated CNC manufacturing on 5 and 4 axis mills. In addition, we offer Multi-axis mill turns, turning, Swiss Turn, and waterjet machining. We also offer post machine surfacing, secondary treatment processes, and sub-assembly services in-house and through a network of validated and approved process suppliers. We produce machined components for the motorsports, aerospace, defense, space, and medical markets.

For more information about RYE, visit