WTO presented numerous innovative tool holder solutions at EMO 2025 including a new generation of intelligent driven tool holders with innovative "smart" technology for process monitoring, tool holders with Automatic Tool Change for turning centers, new Gear Hobbing Units, automatic Broaching Units, a new coolant-driven high-speed spindle CoolSpeed® MAX with two turbines for speeds from 20,000 to 60,000 rpm.

QuickFlex® smart

INDUSTRY 4.0

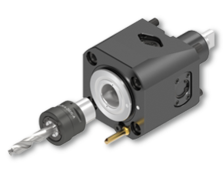

The new generation of Smart Driven Tool Holders QuickFlex® smart with intelligent online process monitoring for high process reliability in fully automated turn-mill center cells.

EMO PREMIERE:

WTO “myTools” App for the digital access to all information (manual, drawing, etc.) via DataMatrix code on the tool holder.

ATC – Automatic Tool Change

INNOVATION

Static and Driven Tool Holders with automatic operated Coromant Capto® clamping system for the automatic tool change at turn-mill centers.