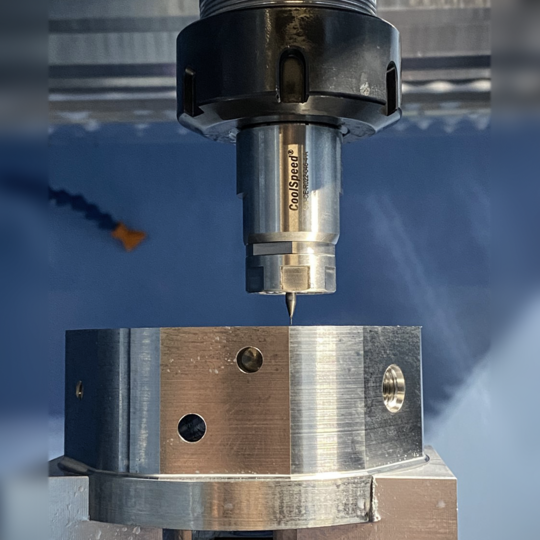

58% faster operation with CoolSpeed® MAX compared to a Machine Spindle

Application: Demo work piece

Machining: pocket milling, slot milling

Total machining time:

- CoolSpeed® MAX: 5:32 minutes

- Machine Spindle: 13:15 minutes

Total time saving: 58%

Machine: Hermle C32

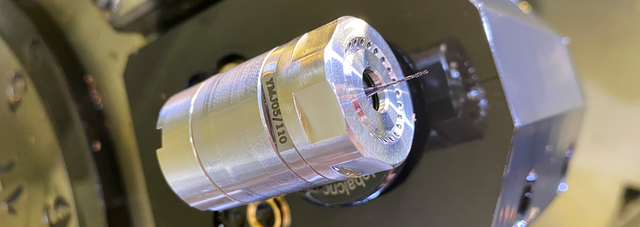

CoolSpeed® MAX: CX-CE-F020-109-FL-SB-A

rpm: 28,000

Driven by: coolant

Coolant Pressure: 798 psi (55 bar)

Size of work piece: 80 mm (depth) x 100 mm (width) x 30 mm (height)

Material: SAE1045

Hardness: 220 HB

Cutting Tool: Gühring RF 100 U 3732 3.000

3 times faster with CoolSpeed® Flex than previous process on 40,000 parts per year

Application: Milling small grooves using a 3 mm ball end mill on a mold part

Machining: Engraving

Time Savings: 3 times faster!

Company: Benmar Fabrication

Machine: Takamaz XW-130

CoolSpeed® Flex: CM-CE-F075-037-FL-A

rpm: 42,000

Driven by: coolant

Coolant Pressure: 240 psi

Size of work piece: 50 mm x 50 mm (2” x 2”)

Material: Die Steel

Making detailed stamps (negative form)

Application: Making custom detailed stamps using a 1/64“ end mill for making precious metal coins and bars

Machining: Finishing

Time Savings: 10x faster than traditional 5K rpm spindle with the ability to use 2x smaller cutting tools than before. CoolSpeed® Flex lowered total machining time from 48 hours to 5 hours.

Total time saving: 43 hours per part

Company: Silverback Precious Metals

Machine: Source Rabbit Micro Mill

CoolSpeed® Flex: CM-CE-F075-037-FL-A

rpm: 60,000

Driven by: coolant

Coolant Pressure: 435 psi

Size of work piece: 2”x2”

Material: AISI 4140 steel, annealed

Hardness: 22 HRC (99 HRB)

High-speed machining stainless steel at 900 inch per minute

Application: Machining complex mold core with 2 mm end mill

Machining: Roughing and Finishing

Machining time: 4.5 hours

Time Savings: Lowered cut time from 12 hours to 4.5 hours on 1.5 million lines of code at a feed rate of 900 ipm (inch per minute) (23.000 mm/min)

Time Savings: 7.5 hours/37,5 %

Company: Fraisa USA

Machine: Hermle C 22 U

CoolSpeed® Flex: CM-CE-F075-037-FL-A

rpm: 70,000

Driven by: coolant

Coolant Pressure: 625 psi

Work piece diameter: 5”

Material: 440C-SS (Stainless Steel)

Hardness: 30 HRC (105 HRB)

Application: finishing operations on highly decorative part using a 1 mm end mill

Machining: Finishing

Time Savings: Total time saved for the job was 350 hours on 200 parts

Total Time Savings: 350 hours for 200 parts

Company: La Forge De Style (USA)

Machine: Haas VF-4SS

CoolSpeed® mini: CM-CE-F025-010-4-A

rpm: 48,000

Driven by: coolant

Coolant Pressure: 290 psi

Work piece diameter: 3”

Material: Nickel Silver

Hardness: 120 HB (45 HRB)

Testimonial: Tom Afflard (La Forge De Style)

„Customer could not have won this job without CoolSpeed® mini. The machine tool is only able to deliver 10,000 rpm on main spindle but with 300 psi of coolant pressure, CoolSpeed® mini runs at 48,000 rpm. Using a 1 mm ball end mill with 4 mm shank dia. and a feed rate of 46 ipm, the cycle time for this job was cut down to 25 minutes. For all the parts, it saved about 350 hours for spindle time.“

Machining Micro Fluid Channels

Application: Using a variety of cutting tool sizes from 1 mm to 0.1 mm and smaller for machining small features on research prototype parts

Machining: Roughing/Finishing/Pocketing/Holes

Time Savings: „The number of hours saved over standard 12k machine spindle would be months of time“ – Jeff Tiedeken

Total Time Savings: “months”

Company: Cutting Time

Machines:

- Matsuura MX330 with ChipBlaster 1000 PSI

- Haas DT1 5 axis with Haas 1000 PSI HP

CoolSpeed® mini: CM-CE-R016-046-4-A

rpm: 60,000-80,000

Driven by: coolant

Coolant Pressure: 500-870 psi

Size of work piece: Varies

Material: Grade 2 Titanium

Hardness: 21 HRC (98 HRB)

Testimonial: Jeff Tiedeken (company “Cutting Time”)

„Currently, we have 3+ machines running CoolSpeed® spindles around the clock! We produce prototype parts specifically for the science community in various materials, a lot of those parts have channels, pockets and holes down to 0.1 mm and sometimes smaller in special cases. It isn't feasible to do small features of that size without relying on spindle speeders. The price and performance allows us to have multiple CoolSpeed® spindles loaded in the tool magazine. We rough with a 1 mm, clean up with a 0.5 mm and finish with 0.3 mm end mills, which speeds up the proccess and reduces the risk of breaking end mills on longer runs. We have one major production job that has been consistent for the last 2 years cutting grade 2 titanium, the number of hours saved over standard 12k machine spindle would be months of time, I can't even imagine doing it any other way than using the CoolSpeed® spindle speeders.”

High-Speed Machining of Torx Screw Heads with CoolSpeed® mini

Application: Pilot drilling with a 2.8 mm drill and pocketing with a 0.6 mm (0.0236“) endmill on Torx Screw Heads

Machining: Pocketing

Machining time per part:

- CoolSpeed® mini: 1:22 minutes

- Swiss Type: 5:30 minutes

Total machining time for 30,000 parts:

- CoolSpeed® mini: 683 hours

- Swiss Type: 2,750 hours

Total time Savings: 2,067 hours!

Company: Area 419

Machine: DMG Mori NLX2500

CoolSpeed® mini: CM-CE-R016-046-4-A

rpm: 35,000

Driven by: coolant

Coolant Pressure: 260 psi

Size of work piece: 0.155”

Material: 303-SS

Hardness: 19 HRC (96 HRB)

Testimonial: Marcus Burciaga (Area 419)

“CoolSpeed has allowed us to make small Torx head parts which would normally be ran on a Swiss Type machine, on our DMG NLX2500 turning center. We were able to cut over 4 Minutes of machine time off EACH part using CoolSpeed. It has literally paid for itself within a week. Being able to spin the micro tool at the required 35,000 rpm vs. the max of the machine at 10,000 rpm has been a huge benefit to our operations.”

Micro Machining with Cool CoolSpeed® MAX und CoolSpeed® Flex

Application: Demo work piece

Machine: brother S700Xd1 Compact Machining Center

Driven by: coolant

Coolant Pressure: 69 bar (1,000 psi)

Size of workpiece: 127 mm x 127 mm

Material: 6061 Aluminium

A:

CoolSpeed® MAX

Machining: pocket milling

Tool: endmill, 2 mm

rpm: 45,000

Feed: 150 ipm

B:

CoolSpeed® MAX

Machining: circular channels

Tool: Ball nose endmill, 3 mm

rpm: 45,000

Feed: 500 ipm

C:

CoolSpeed® Flex

Machining: drilling

Tool: pilot drill 0,0079”

rpm: 45,000

Feed: 2.5 ipm

87% faster operation with CoolSpeed® mini compared to a Machine Spindle

Application: Demo work piece

Machining: pocket milling, slot milling, drilling and engraving

Total machining time:

- CoolSpeed® mini: 2 minutes

- Machine Spindle: 15:45 minutes

Total time saving: 87%

Machine: Hermle C32

CoolSpeed® mini: CM-CE-F025-010-4-A

rpm: 60,000

Driven by: coolant

Coolant Pressure: 580 psi (40 bar)

Size of work piece: 38 mm x 38 mm x 10 mm

Material: SAE4140

Milling 86% faster with CoolSpeed® than with standard Driven Tool Holders Application: Part for electronics assembly

Maschining: milling

Total machining time:

- CoolSpeed® mini: 2 minutes

- Standard driven tool holders: 15 minutes

86% Faster!

Machine: Citizen Cincom L32

CoolSpeed® mini: CM-CE-R016-046-4-A

rpm: 55,000

Driven by: coolant

Coolant Pressure: 319 psi (22 bar)

Size of work piece: 26 mm x 5 mm

Material: 6061 T6 Aluminium

Engraving letters with CoolSpeed®

Application: Demo work piece for complete part machining

Machining: engraving

Machining time CoolSpeed® mini: 11 seconds

Machine: Okuma LB3000 EXII

CoolSpeed® mini: CM-CE-F016-046-4-A

rpm: 50,000

Driven by: coolant

Coolant Pressure: 230 psi (16 bar)

Outer diameter of work piece: 69 mm

Material: AISI 1018

Hardness: 126 HB (71 HRB)

11 Seconds!

Drilling holes dia. 0.0189“ on a turning center fast and efficient with high-speed Application: High-speed drilling of 12 holes diameter 0.0189“ and depth 0.300“ with a right angle CoolSpeed® mini spindle mounted in a boring bar holder

Machining: drilling

Machining time CoolSpeed® mini: 80 seconds

Machine: Doosan Lynx 2100LSY

CoolSpeed® mini: CM-CI-R016-016-4-A

rpm: 75,000

Driven by: cutting oil

Coolant Pressure: 870 psi (60 bar)

Size of work piece: Approx. 1” diameter x ¾”

Material: Copper

Hardness: 51 HRB

80 Seconds!