A new dimension of high productive gear machining: Skiving of ID and OD gears and splines on CNC Turning Centers with the innovative Power Skiving unit from WTO.

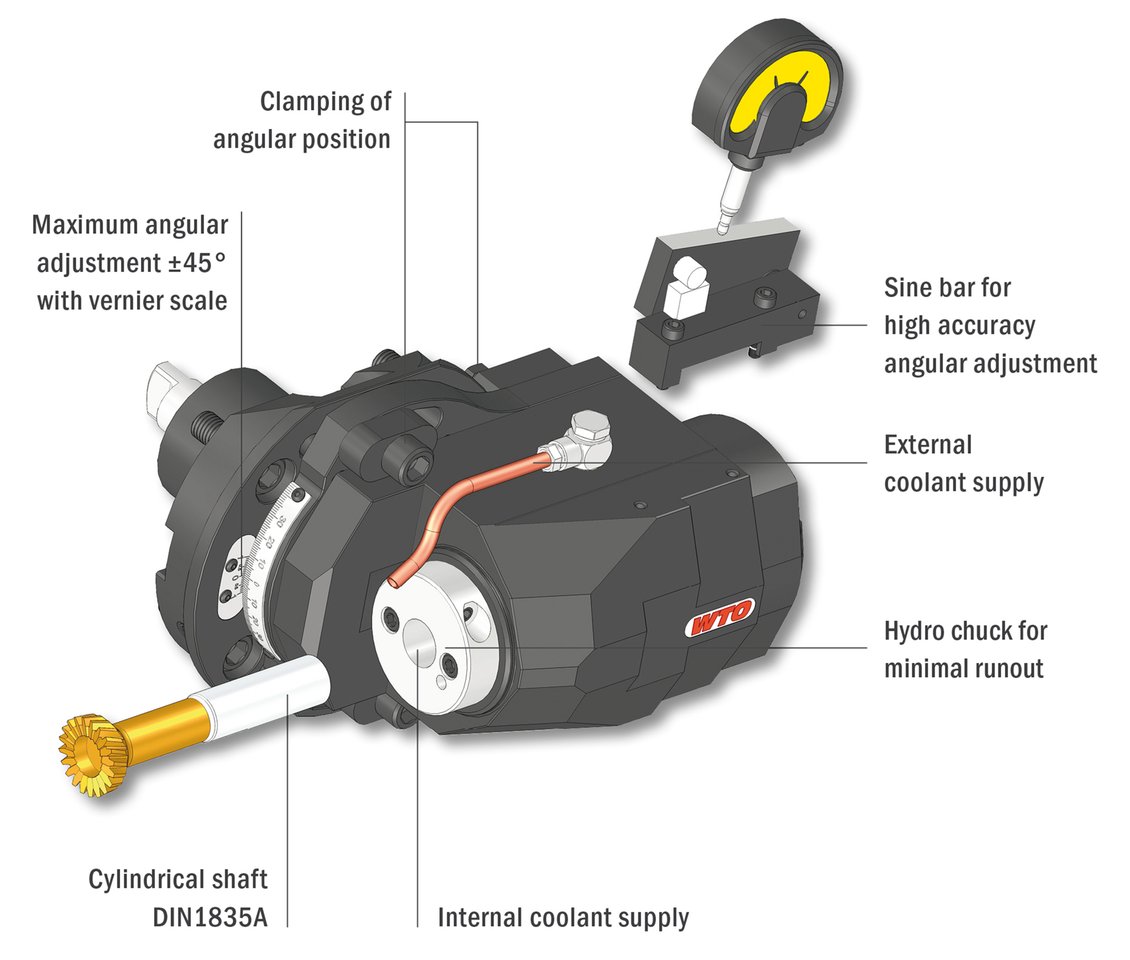

The WTO Power Skiving unit offers high stiffness and runout accuracy. The hydro chuck spindle enables an accurate and quick cutting tool change.

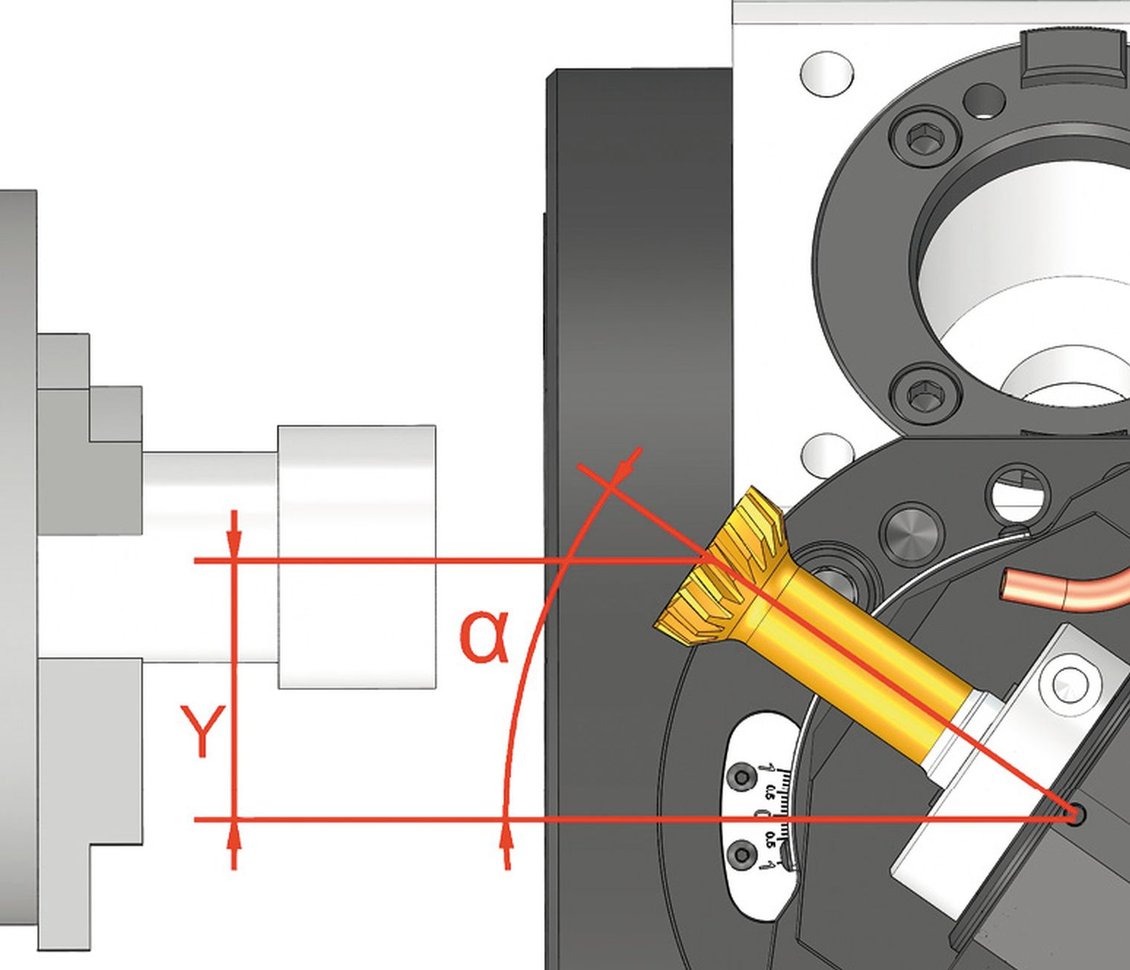

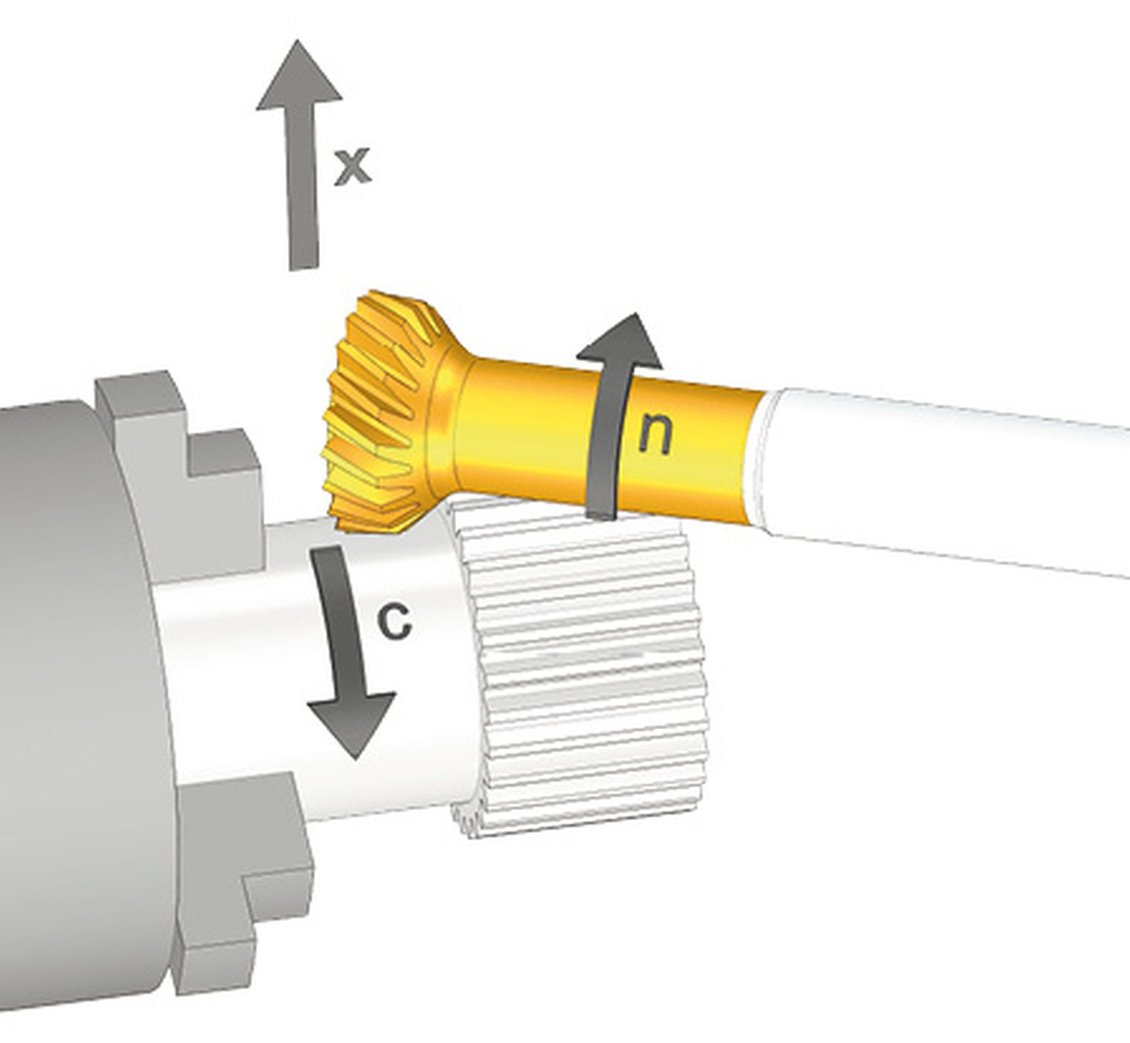

The workpiece axis and the skiving tool axis must be related to each other in a defined angle (α).

The offset of the cutting tool (Y) caused by rotating to the defined angle (α) must be compensated with the Y-axis of the machine.

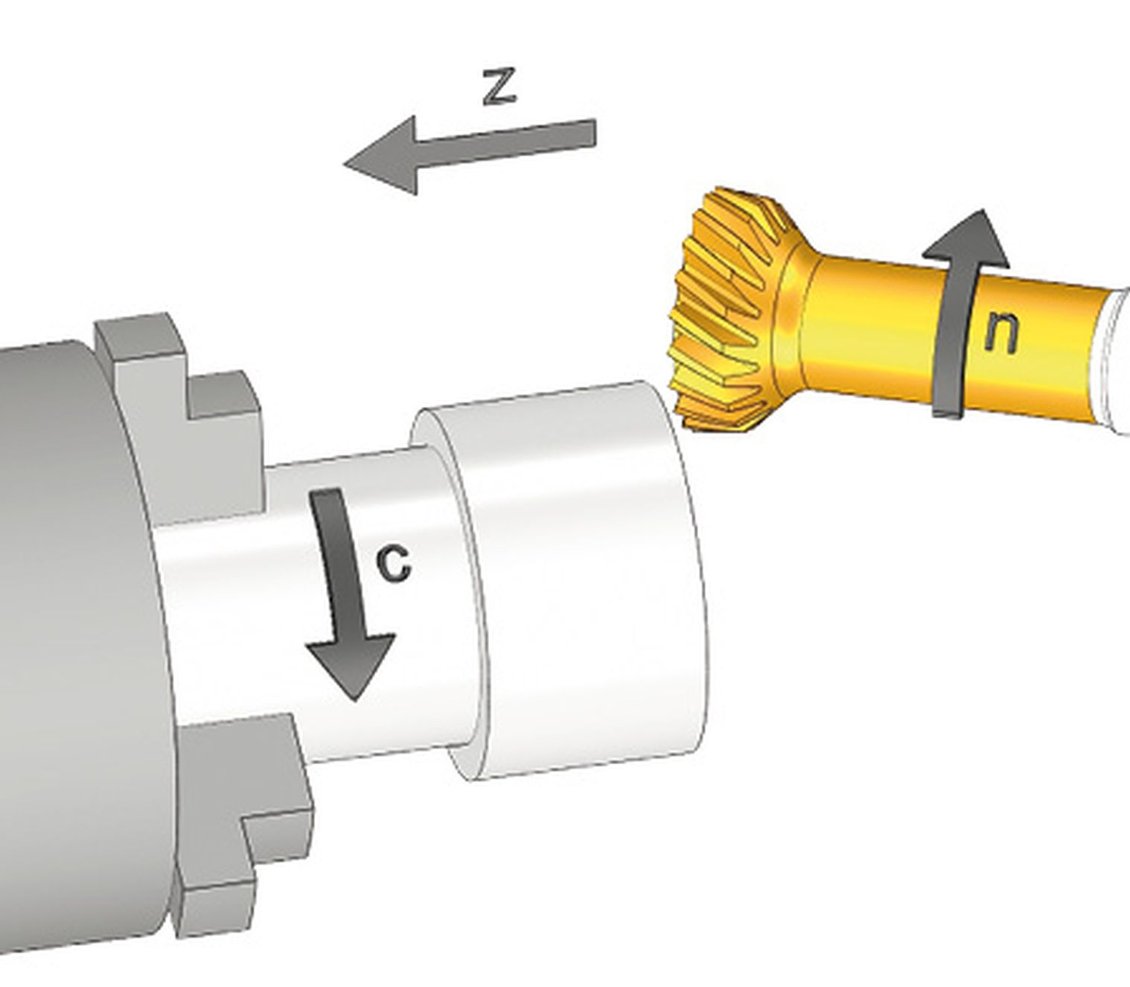

Synchronization of work piece and tool rotation.

Feed movement in Z-axis.

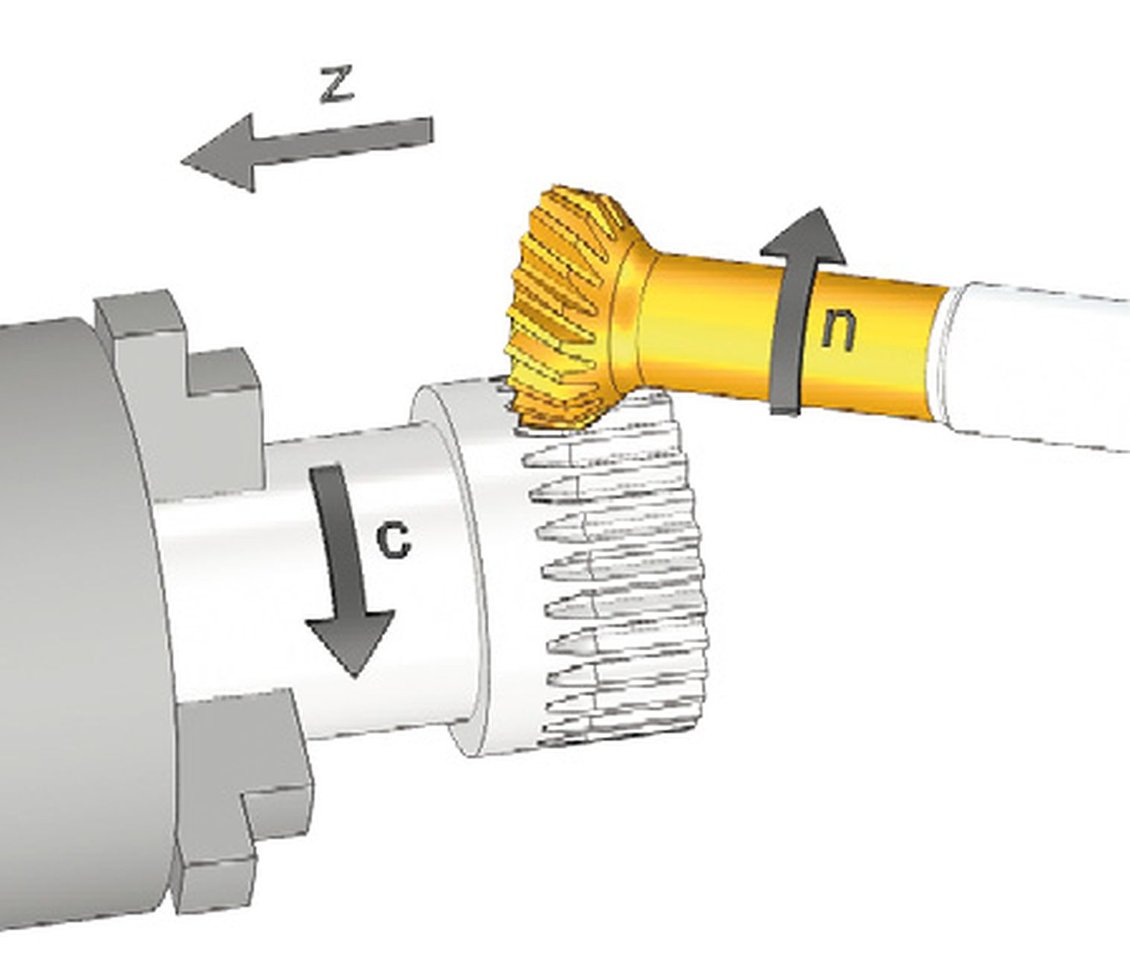

When skiving is finished the cutter has to move towards X.

Please consider:

At the end of the gear/spline there must be sufficient clearance for the cutter.

Internal involute spline

Spline

Spur gear

Helical gear

Power Skiving Unit (PDF, 1,2 MB)

Product Portfolio (PDF, 4,2 MB)

Please refer to our Online Catalog for the precision toolholders that are suitable for your machine: